Kuhn - LSB 890 D OPTICUT

|

KUHN LSB D Series balers have been built from the ground up to provide you with one of the toughest, most reliable large square balers on the market. The KUHN LSB 890 D (3x3) and 1290 D (3x4) large square balers combine high output and maximum reliability to serve as a perfect fit for commercial hay producers. The D Series balers have been designed with simple, yet efficient features including Integral Rotor Technology and the Power Density System to produce rock-hard, square-edged bales in all crop conditions. Rasspe® double knotters are not only reliable, but allow you to increase bale density by 10% and the number of bales per hour by 15%. Dual hydraulic-driven fans keep our double knotters clean and our competitors envious. KUHN LSB balers feature the simplest drive system in the industry, fewest moving parts, heaviest standard flywheel and longest standard bale chamber to provide outstanding durability and performance. All KUHN LSB balers are ISOBUS compatible, therefore will not require a separate VT monitor for the baler. You can easily change settings such as bale density or knife activation from the comfort of your tractor seat. |

|

Intake Options to Meet Your Operation’s Needs

The pickup is designed to match the full capacity of the baler. The wide, 91” pickup, with narrow tine spacing, will leave your fields clean. Straight pickup tines help release the crop and reduce crop wrapping. Uniquely shaped crop guides result in more aggressive and efficient pickup by exposing more of the tine when needed, and by pulling the crop away from the tines as it approaches the intake. The pickup roller compresses the crop against the pickup tines reducing friction, thus reducing leaf loss and increasing baler efficiency by evening out the windrow. In extreme conditions, pivoting gauge wheels ease wheel and tire stress. To better meet your operation's specific needs, there are three intake options available. Select from one one of our three patented Integral Rotors – the non-cutting OptiFeed rotor, or the 15- and 23-knife OptiCut cutting rotors. Availability dependent on LSB model – See Specifications |

|

The crop feeder allows for up to 15% more capacity in heavy windrows. The crop feeder compresses large windrows down into the integral rotor to improve crop flow. Standard on the LSB 1290 D, optional on the LSB 890 D. |

|

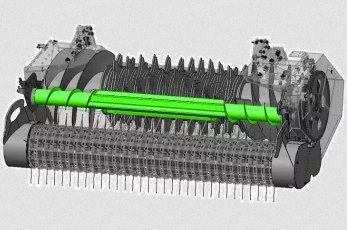

Available on KUHN SB Series balers is our patented Integral Rotor Technology found on OptiFeed and OptiCut models. This simple, low-maintenance intake system guarantees an enormous throughput capacity at all times. The short distance between rotor and pickup tines maintains consistent crop flow. The design of this force-fed intake makes higher forward speeds possible for increased productivity and reduces crop damage. The Integral Rotor is provided with rotor tines made out of Hardox® wear plates. Hardox combines extreme hardness and toughness to reduce rotor tine wear. Longer wearing life of the rotor tines will help to provide time and money savings for the operator. |

|

When crop cutting is not required, the OptiFeed system ensures a controlled and consistent crop flow to the prechamber. This rotor design helps even out windrows by moving hay where needed for consistent bale formation. This force-fed, non-cutting intake is the perfect solution for handling tough crop conditions such as cornstalks, short straw and high-moisture crops. |

|

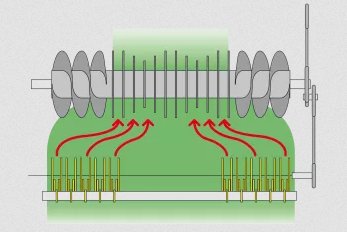

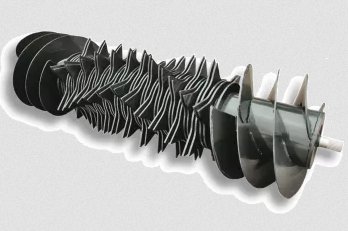

With 20 years of experience behind our cutters, the OptiCut (OC) cutting rotors are designed for unlimited intake capacity and excellent cutting quality. KUHN (OC) cutting rotors, with elliptical shaped rotor tines, are acknowledged by users as one of the best cutting systems on the market. The silage is guided and drawn down to the knives from an early stage which improves flow and cutting performance and also prevents unwanted plugging.

OptiCut 15

OptiCut 23 With just two levers, you can easily choose from the following knife group configurations: 0-11-12-23. Together, with the standard slide tray for easy knife changing, you not only invest in cutting quality but, above all, in driver comfort. |

|

Consistent, Dense, and High-Quality Bales

Power Density – The KUHN Solution

Power Density – The KUHN SolutionThe Importance of Bale Shape: Consistently shaped bales provide more than just aesthetic appeal. A dense, consistently filled bale represents quality in every form. Square bales are easy to handle and stack. In addition, they are much more stable during transport than a poorly formed bale. In silage applications, a square-edged bale indicates less air content, resulting in higher quality feed. The KUHN Power Density system, a single feeder fork design, proves that a well-engineered component can eliminate complexity. This system ensures consistently filled flakes and results in heavy, square-edged bales regardless of the windrow condition. The single feeder fork combines two functions into one mechanism, eliminating unneeded components and complexity. KUHN’s exclusive Power Density system runs at twice the speed of the plunger allowing a minimum of one flake formed per plunger stroke. This creates consistent bale shape and excellent density. |

|

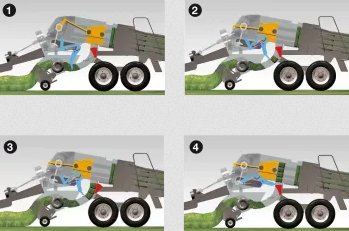

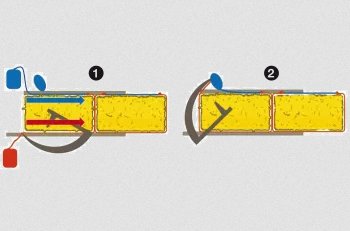

1- The integral rotor actively delivers the crop to the chamber. 2- The single-acting feeder fork (blue) lifts the feed up to the measuring plates (red). 3- The single-acting feeder fork continues to form the bale flake until the measuring plate is pushed back with a predetermined force. 4- Once the measuring plate is pushed back, it locks the single-acting feeder fork to push the perfectly formed flake into the bale chamber. |

|

The specially designed bale chamber of the KUHN SB machines is the result of more than 35 years of experience in large square balers. With the 10-foot long bale chamber, there is plenty of space to form a rock-hard, square-edged bale. The combination of aggressive retainers and special wedge-shaped doors brings maximum compaction and gentle expansion of the bale. Forty-six plunger strokes per minute result in a high bale capacity. The plunger is guided by four large rollers with a 5" diameter for maximum service life. |

|

The SB 890 and SB 1290 are equipped with a double-knotting system. With the electronic knotter control, the driver has accurate information concerning twine tension at all times and receives an alarm if an issue arises. The knotting progress can be monitored directly from the tractor cab. During baling, an upper (blue) and lower (red) twine is fed to the bale, because the twine is not slipping around the bale there is no tension on the twine during the bale formation. Step 1: As the bale reaches the desired length, the needles (gray) are activated and move upward to the knotter to start the knotting cycle. In this first step the bale is finished with the first knot. Step 2: Once the first knot has finished the bale, the second knot connects the upper and lower twine again so the bale can be formed without tension on the twine during knotting. |

|

Heavy-Duty Driveline, Maximum Protection

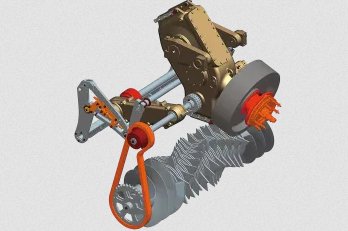

KUHN uses a combination of synchronized gearboxes, drivelines and oversized chains designed for maximum life and limited maintenance. The driveline layout is simple, clean, and easy to service and maintain while minimizing the overall number of moving parts. |

|

The pickup, integral rotor and feeder fork are protected with cam-type clutches, which are automatically activated in the event of an overload. The clutch re-engages when the operator reduces the PTO speed. This allows the operator to restart the stalled component from the driver’s seat, reducing overall downtime that is typical with slip clutches and shear bolts. Another benefit of these clutches is that they give the ability to drive at a constant speed without worrying about plugging. Heavy, large-diameter flywheels are featured on all SB models. The large flywheel creates the force needed to pack the bale. This also reduces the horsepower required, and the torque spikes through the components and driveline, resulting in less fuel consumption and wear for extra longevity. |

| Download Brochure | Download |