Meyer Manufacturing SXR/SXL Crossfire Auger Spreader / 1,355 - 2,617 gallon

|

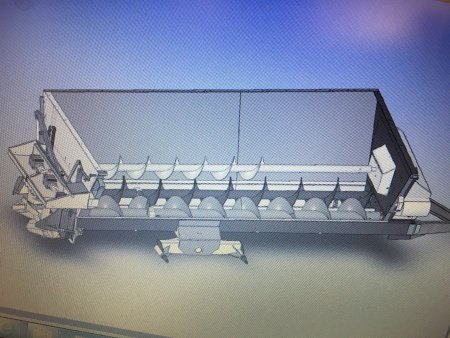

The New Meyer Crossfire Series V-Spreader combines the technology and performance of our Industrial Series models into a smaller configuration to give you maximum performance in the 260 - 540 bushel range. Our unique Rear Discharge System is unlike all others, incorporating a pantented rear discharge system with two shaft-driven vertical expellers for premium spread performance. The expellers are fed by an aggressive 3-auger system which powers through pack manure, semi solids, sand sludge, slurry, litter, biosolids, and certain lime and compost products. Rear Discharge keeps your tractor and spreader clean while maximizing the value of the product you are applying - it just makes sense! THE NEW CROSSFIRE MODELS REPLACE THE FORMER V-MAX & V-FORCE MODELS - get ready to be impressed with a superior spread pattern. |

Pull Type Models in 4 sizes / Truck Mount Version available soon! |

|

SXL Models The SXL Version Crossfire is available in 2 models (4 sizes). SXL2636 no ext - 1,355 gallons / SXL2636 with 9" ext - 1,745 gallons / SXL3954 no ext - 2,033 gallons / SXL3954 w/9" ext - 2,617 gallons. Meyer SXL is your low load height leader! |

|

SXR Models The SXR Version Crossfire is available in 2 models (3 sizes). SXR400 no ext - 1,870 gallons / SXR400 w/4" ext - 2,150 gallons / SXR500 no ext - 2,424 gallons |

|

Meyer patented straight-line flow - provides the ultimate spread performance. Better pattern, faster unload time, less horsepower & minimal wind drift!  |

|

Rear Unload Rules! When it comes to spreading, keep the mess behind you. Provides superior application too.  |

|

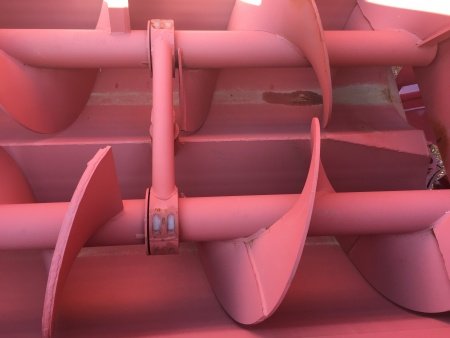

3 auger system, only one of its kind! Lower 20" augers feed the door while the upper 13" auger levels the load forward and eliminates bridging. |

|

Thanks to the dual lower auger arrangement, the Meyer spreader body is wide down low. This means we can maintain a lower load height with maximum capacity! The other advantage is the near elimination of bridging which is common in side delivery spreaders. |

|

independent Lower Auger Shear Bolt Protection, a Meyer exclussive. Allows you to protect an obstructed auger while still unloading a majority of the load with the other auger. Bound to save you work! |

Heavy Duty Drivetrain - Crossfire models feature #120 final drive chains #80 expeller and first reduction. HD jackshafts / spring chain tensioning / remote greasing on hard to reach spots! The auto roller chain oiler is standard for added convenience and extended chain life. |

Automatic Roller Chain Oiler is standard. Oils all roller chains each time you cycle the tailgate. Eliminates reduced access and manure contamination associated with oil bath systems. |

Sectionally Flighted 20" Lower Augers propel material to the rear of the spreader. Full auger flighting / No Paddles to wrap, freeze or wedge material |

Our Revolutionary T-Post auger hold-down retains a nylatron (non maintenance) bushing and maintains tight auger tollerance to the tank floor. Provides you more complete cleanout! |

Vertical Twin Expellers pulverize material for smooth, even application. This machine bands material across the back like a fertilizer spreader would, unlike side delivery units that attempt to chuck all the product out one side. Paddles are replaceable and reversible! |

|

Shock Load Coupler System Check out the Shock Load Coupler System.....Drastically reduces "shock/stress" related to frozen manure and foreign objects in your material. This dampening system combined with a torque disconnect clutch on the rear of the CV PTO shaft combine to protect your expeller drive system.  |

Direct shaft drive expellers (includes our shock-load coupler). No chains on the rear of this spreader. Crossfire models feature a new overrunning clutch system on the expeller drive to reduce backlash on the drivetrain. |

|

Easy Cleanout / Hinged Panel Meyer Crossfire models provide a hinged expeller side panels for easy access / easy cleanout!  |

540 CV PTO is standard - 1000 CV PTO is optional. Both incorporate a torque disconnect clutch to protect your investment. |

All Meyer Crossfire models feature a strong, custom formed channel frame. Stress from the hitch, axles and body are transmitted through the frame network, not the body. This design eliminates stress cracking long term. Take a look at the unibody design on most other V-type spreaders! |

|

Hitch Design All Crossfire Models feature a longer hitch design for more clearance. The SXR500 features an additional 7" of length, this is optional on all other Crossfire versions. (Long Hitch pictured here - standard on SXR500)  |

|

HD Axle System This HD, offset tandem on the Crossfire models features 3" spindles on a SXL3954 & SXR500 (2 3/4" spindles on all other models) - all are 8 bolt. 10 bolt hub/spindle option available on SXL3954 & SXR500 models with certain specific tire sizes.  |

|

Tire Options Many tire/rim alternatives available depending on model. Choices include rib implement or used truck tires.  |

|

Splash Protection Angled splash shields front & rear are standard on the SXR500 model while all others feature an angled splash shield system in the front and low-pro flat splash protection in the rear for low clearance applications.  |

|

LED turn signal lighting standard / Redesigned tailgate & lift mechanism The door opening of the new Crossfire is WIDER and TALLER allow for faster unloader in solid manure. The tailgate is reinforced and the gate tracks are redesigned and poly-lined for better long term performance, even in cold weather. The tailgate pivot arm is stronger and has a dual hinge point to avoid sticking & wedging.  |

|

Hydraulic Lid Option This Hydraulic Lid feature provides cleaner transportation and less odor pollution. Right or Left hinge available and a port hole is standard equipment. (SXR500 only)  |

| Name | Link |

| Product Brochure | Download |