Kuhn - 3115 STATIONARY

| KUHN Knight 3100 Series Reel Auggie® mixers offer the same quality mixing performance and dependable service that has been their hallmark. The time tested, standard reel and auger design provides a fast, thorough mix for a fluffy, palatable ration. Quality components and a rugged design help ensure reliability and long life. These mixers are available in trailer, truck and stationary models with capacities ranging from 150 to 200 ft³. These machines also offer a low standard loading height for easy loading with skid steers. |

|

The Reel Advantage

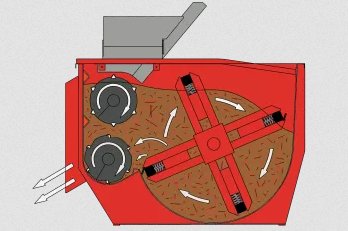

The Reel Auggie® mixer blends by gently lifting and tumbling all feed ingredients. This produces a fluffy, more palatable ration that promotes increased consumption and better herd health. The gentle tumbling action of the large-diameter reel works together with the two side blending augers to produce end-to-end and side-to-side mixing action. The reel design eliminates much of the force and pressure inherent to most other mixer designs. This results in lower horsepower requirements, reduced machine wear and less feed breakdown. |

|

KUHN Knight reel mixers provide a consistent mix, even with small batches, for a balanced ration from beginning to end. Their quick, even discharge with a more complete cleanout helps save time and maximizes efficiency. |

|

With a high discharge point, these mixers allow for the use of a simple slide tray in most feeding situations. The long tray makes it easy to feed deeper into most bunks while preventing feed loss from the wind. This dependable, low-cost option also results in less maintenance. |

|

Built to Last

Sturdy Box Construction

Sturdy Box ConstructionSturdy end panels, combined with heavy-duty reel and auger hoppers, lengthen machine life. The upper and lower shear angles strengthen the mixer box, improve end-to-end mixing and increase hay processing efficiency. The large door opening allows for fast discharge. |

|

The rectangular tube frame construction, with steel bumper, provides strength, reliability and added unit protection. Large-diameter spindles provide optimum strength and durability. The adjustable and reversible clevis hitch adapts to different drawbar heights. |

|

The dependable, heavy-duty roller chain drive runs in oil and has spring-loaded, self-aligning poly tighteners for long life. Final drive shafts and sprockets are splined for strength and serviceability. |

|

Self-aligning bearings are mounted on the outside of the mixer chamber for easy service and extra life. Polyethylene seals help prevent bearing contamination. Nylon reel bearings, with polyethylene seals, provide simplicity, long-life and help prevent oil bath contamination. |

|

Tailor Your Machine

To best suit your feeding needs, you can choose from a slide tray, chain and slat conveyor, or a 3-auger discharge to be equipped on your 3100 Series mixer. Slide Tray The high discharge point of the Reel mixers allows use of the simple, dependable, low-cost slide tray in most applications. It has simple hydraulic controls and the long discharge tray reaches deeper into bunks to prevent feed loss from the wind. Magnets are standard on slide tray. Chain and Slat Conveyor Rugged chain and slat conveyor options provide the ultimate in durability and long life. Heavy-duty components ensure reliable service and multiple conveyor length options offer unmatched flexibility to match different feeding situations. 3-Auger Discharge The 3-auger discharge allows adjustment for feeding into higher bunks. It has a simple, hydraulic drive that provides smooth, even discharge. Long lasting, poly chute liners help prevent rust and limit wear. The 3-auger discharge comes standard with fixed tip-off and built-in magnets. |

|

To suit your operation’s needs, KUHN Knight 3100 Series mixers are available in trailer or truck-mounted or configurations. Trailer models are the most popular configuration as they are the most economical and versatile. Being detachable allows the tractor to be used elsewhere on the farm when not in use for feeding. Truck-mounted models are a suitable option for those that have to feed cows at several different locations, with large travel distances. This option allows a feeder to quickly get from the mixing location to the feed bunk and back again. Whether mixing wood chips or a ration for your livestock, KUHN Knight 3100 stationary mixers are ideal for maximizing feeding efficiency and mixer throughput on any operation. Stationary mixers are perfect for producers with centralized feed storage and multiple mixers running throughout the day. By incorporating centralized mixing, one loader operator is often able to keep multiple mixers constantly running, greatly increasing mixing capacity and reducing labor. Also, with the addition of delivery boxes, the mixers do not experience the downtime from driving location to location, and in turn do not receive the additional stress which can be seen from constant travel. |

| Download Brochure | Download |